clack ws1 programming manual

The Clack WS1 control valve is a fully automatic, glass-filled Noryl valve designed for water softeners and filters, regulating system cycles efficiently and reliably.

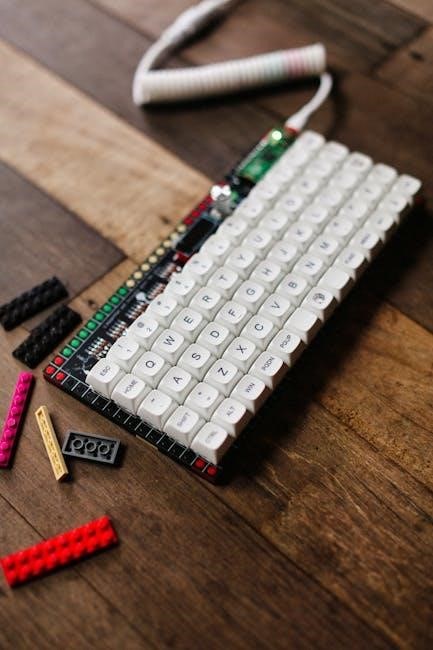

1.1 Overview of the Clack WS1 Series

The Clack WS1 series is a fully automatic control valve designed for water softeners and filtration systems. Made from durable glass-filled Noryl, it ensures reliable operation and long service life. The valve directs and regulates all system cycles, serving as the central control unit. It supports various configurations, including simplex water softeners, and is compatible with multiple regeneration options. Key features include delayed regeneration, custom programming, and advanced flow control. The WS1 series is known for its ease of installation and maintenance, making it a popular choice for water treatment systems. Its robust design and versatile functionality cater to both residential and light commercial applications, ensuring efficient and consistent water treatment processes.

1.2 Purpose of the Programming Manual

This manual serves as a comprehensive guide for the Clack WS1 control valve, detailing its operation, installation, and maintenance. It provides essential information for water treatment equipment manufacturers, installers, and service personnel. The manual covers valve functions, cycles, programming options, and troubleshooting procedures. It aids in selecting the appropriate valve configurations and ensures proper system setup. Additionally, it includes diagnostic tools and maintenance schedules to optimize performance and extend the valve’s lifespan. The manual is designed to help users understand and utilize the WS1 series effectively, ensuring efficient and reliable operation of water softening and filtration systems.

Technical Specifications of the Clack WS1

The Clack WS1 control valve is constructed from durable glass-filled Noryl, designed for water softeners and filters, offering reliable operation and compatibility with various regeneration options.

2.1 Valve Body and Injector Specifications

The Clack WS1 valve body is made from high-strength glass-filled Noryl, ensuring durability and chemical resistance. The injector system features precision-engineered nozzles for optimal flow control and minimal pressure drop. This design allows for smooth operation across various water treatment applications. The valve body is compatible with both water softeners and filtration systems, making it versatile for different setups. Proper orientation of the injector ensures efficient water flow, with rounded edges guiding water toward the washer face. These specifications contribute to the valve’s reliability and performance in residential and light commercial environments.

2.2 Drive Assembly and Flow Control Details

The drive assembly of the Clack WS1 control valve is designed for precise and reliable operation, featuring a robust gear and piston mechanism. This assembly ensures smooth transition between cycles, such as backwash, rinse, and service modes. The flow control system includes a piston and port design, which regulates water flow efficiently during regeneration and normal operation. The valve’s flow control ensures minimal pressure drop while maintaining optimal water distribution. Proper orientation and installation of the drive assembly are critical to prevent misalignment and ensure long-term performance. The flow control system is also adaptable to various water treatment applications, making it suitable for both water softeners and filtration systems.

Installation Requirements

Proper installation of the Clack WS1 control valve requires precise plumbing connections, correct orientation, and adherence to manufacturer guidelines to ensure optimal performance and longevity of the system.

3.1 Pre-Installation Checks

Before installing the Clack WS1 control valve, ensure all components are included and undamaged. Verify compatibility with your water treatment system and plumbing setup. Check for any signs of wear or damage on the valve body, injector, and drive assembly. Ensure proper orientation of the valve to align with water flow directions. Confirm the system is drained and pressurized correctly to avoid leaks or damage during installation. Review the manual for specific requirements and safety precautions. Ensure all necessary tools and materials are available for a smooth installation process. Proper preparation will help prevent issues and ensure optimal performance of the Clack WS1 control valve.

3.2 Step-by-Step Installation Guide

Mount the Clack WS1 control valve securely, ensuring it is level and properly aligned with the system. Connect the water supply lines, making sure they are correctly oriented and supported to prevent misalignment. Install the drive assembly and synchronize it with the valve’s operation. Connect the drain line according to the specified DLFC orientation, directing water flow toward the washer face. Program the valve settings to match your system’s requirements, such as regeneration cycles and flow rates. Finally, perform a test cycle to ensure proper operation and address any leaks or issues immediately. Follow all safety guidelines and manufacturer recommendations for a successful installation.

3.3 Post-Installation Testing

After installation, perform a thorough test of the Clack WS1 control valve to ensure proper function. Start by visually inspecting all connections for leaks and verifying that the valve is correctly aligned with the system. Activate a manual regeneration cycle to observe the valve’s operation during each phase, ensuring smooth transitions between cycles. Check the flow rates and backwash operation to confirm they match the system’s specifications. Monitor the valve’s response to programming settings and verify that all cycles complete without interruption. Address any issues promptly, such as adjusting settings or tightening connections, to ensure optimal performance and reliability of the water treatment system.

Programming and Setup

The Clack WS1 offers intuitive programming options, including cycle configuration, regeneration timing, and flow control settings, ensuring efficient system customization and operation. This guide provides step-by-step instructions for setup and customization.

4.1 Understanding Cycle Operation

The Clack WS1 control valve operates through predefined cycles to manage water treatment processes efficiently. These cycles include regeneration, rinse, and backwash phases, ensuring optimal system performance. The valve automates these cycles based on programmed settings, such as time or water usage. Understanding the sequence and purpose of each cycle is crucial for proper system operation. For instance, regeneration prepares the resin for reuse, while backwash cleans the filter media. Delayed regeneration options allow flexibility, enabling users to schedule cycles during off-peak hours. Familiarizing yourself with these cycles ensures the system runs smoothly, maintaining water quality and extending equipment lifespan. Proper cycle management is key to optimal performance.

4.2 Programming Modes and Options

The Clack WS1 control valve offers multiple programming modes to suit different operational needs. Users can choose between time-initiated or manual regeneration modes, providing flexibility in system management. The time-initiated mode allows scheduling regeneration cycles at specific intervals, while the manual mode enables immediate regeneration when required. Additional options include delayed regeneration, which postpones cycles to off-peak times, and custom settings for cycle duration and frequency. These features ensure tailored operation based on water usage patterns and system requirements. The valve also supports key sequences for locking and unlocking program settings, preventing unauthorized changes. These programming options enhance user control, ensuring efficient and optimized system performance. Proper use of these modes guarantees reliable operation and extends equipment longevity.

4.3 Adjusting Valve Settings

Adjusting the Clack WS1 control valve settings involves calibration to ensure optimal performance. The valve allows customization of regeneration cycles, flow rates, and timing. Users can modify settings via the control interface, with options to delay regeneration or initiate immediate cycles. Proper orientation of the DLFC (Downflow/Loop Flow Control) is crucial for correct water flow direction. Silicone-based lubricants are recommended for maintenance to prevent damage to O-rings and plastic components. Regular adjustments ensure the valve operates efficiently, maintaining system effectiveness. Always refer to the manual for specific calibration procedures to avoid improper configuration and potential system issues. Correct settings ensure reliable operation and longevity of the valve.

Diagnostics and Troubleshooting

The Clack WS1 control valve includes diagnostic features to identify and resolve common issues. Use diagnostic tools and troubleshooting guides in the manual to address malfunctions effectively.

5.1 Common Issues and Solutions

Common issues with the Clack WS1 control valve include improper water flow, regeneration delays, or system malfunctions. Solutions involve checking valve orientation, ensuring correct programming, and verifying salt levels in brine tanks. Lubricating components with silicone-based products can prevent damage to O-rings and plastic parts. Additionally, ensuring proper installation fittings and avoiding hydrocarbon-based lubricants are crucial. The manual provides detailed troubleshooting steps, such as restarting regeneration cycles or adjusting flow control settings. Regular maintenance, like cleaning and lubrication, can prevent many issues, ensuring optimal performance of the valve in water softening or filtration systems.

5.2 Diagnostic Tools and Techniques

Diagnostics for the Clack WS1 control valve involve using specific tools and methods to identify and resolve issues. Key diagnostic tools include the valve’s built-in programming interface and external devices like multimeters. Techniques involve checking the valve’s orientation, ensuring proper installation fittings, and verifying the system’s salt levels. Additionally, using the correct key sequences to lock and unlock program settings can help troubleshoot malfunctions. Regularly inspecting for worn or damaged parts, such as O-rings, and ensuring proper lubrication with silicone-based products are essential diagnostic steps. Monitoring regeneration cycles and flow control settings can also help pinpoint system errors, ensuring efficient operation of the valve in water treatment systems.

Maintenance and Service

Regular cleaning of the valve and injector ensures optimal performance. Use silicone-based lubricants on all components to prevent damage. Replace worn parts like O-rings and seals promptly.

6.1 Cleaning and Lubrication Guidelines

Regular maintenance ensures the Clack WS1 valve operates efficiently. Clean the valve body and injector periodically with mild detergent and water to remove mineral buildup. Lubricate moving parts with silicone-based lubricants only, as hydrocarbons can damage components containing O-rings or plastics. Avoid using harsh chemicals or abrasive materials that may scratch surfaces. Proper lubrication prevents wear and ensures smooth operation. Always follow the manufacturer’s recommendations for cleaning solutions and lubricants. Regular maintenance extends the valve’s lifespan and maintains system performance. Refer to the manual for specific cleaning intervals and procedures tailored to your system’s usage and water conditions.

6.2 Replacement of Wearable Parts

Regular inspection and timely replacement of wearable parts ensure optimal performance of the Clack WS1 control valve. Key components like O-rings, seals, and the valve screen may wear over time and require replacement. Use genuine Clack replacement parts to maintain reliability. When replacing parts, ensure the system is turned off and drained to avoid water damage or leakage. Apply silicone-based lubricants to moving parts during reassembly. Refer to the manual for specific replacement procedures and diagrams. Proper replacement prevents leaks, ensures smooth operation, and extends the valve’s lifespan. Always follow safety guidelines and manufacturer recommendations for part replacements and system maintenance.

Warranty Information

The Clack WS1 control valve is covered by a limited warranty for defects in materials and workmanship. The warranty period varies based on usage and conditions. Refer to the warranty section in the manual for specific terms and conditions. Proper installation and maintenance are required to uphold warranty coverage. Contact Clack support for any warranty-related inquiries or claims. Always ensure compliance with manufacturer guidelines to maintain warranty validity and ensure optimal valve performance throughout its lifespan.

7.1 Warranty Coverage and Conditions

The Clack WS1 control valve is backed by a limited warranty covering defects in materials and workmanship under normal use. The warranty period varies depending on the application and operating conditions. Proper installation and maintenance, as outlined in the manual, are essential to maintain warranty validity. Any unauthorized modifications or use of non-approved parts will void the warranty. For detailed terms and conditions, refer to the official Clack WS1 manual or contact Clack support directly. Ensuring compliance with manufacturer guidelines is crucial to uphold warranty coverage and ensure optimal performance throughout the valve’s lifespan.

7.2 Contacting Clack Support

For assistance with the Clack WS1 control valve, users can contact Clack support through various channels. The official Clack website provides detailed contact information, including phone numbers, email addresses, and a support portal. Additionally, the PDF manual includes a section dedicated to support resources, ensuring easy access to troubleshooting guides, repair services, and warranty claims. Clack also offers technical support for OEMs and service personnel, aiding in complex installations or maintenance. For specific inquiries, such as parts replacements or operational guidance, reaching out to Clack directly is recommended. Ensure to have the valve model number and order number (e.g., V3008-02) readily available for efficient support.

Advanced Features

The Clack WS1 offers advanced features like delayed regeneration and custom programming settings, enhancing control over water treatment cycles for optimized performance and flexibility in system operation.

8.1 Delayed Regeneration Option

The delayed regeneration option on the Clack WS1 allows users to schedule regeneration cycles at convenient times. This feature ensures minimal disruption to water usage, as the system can postpone regeneration until a later time. By pressing specific buttons, users can delay regeneration or initiate it immediately. The valve indicates regeneration status through an arrow pointing to “REGEN” when scheduled. This option is particularly useful for households with fluctuating water demands, providing flexibility and efficiency in system operation. The manual regeneration capability also enables quick overrides when necessary, ensuring optimal performance tailored to user needs and preferences.

8.2 Custom Programming Settings

The Clack WS1 control valve offers customizable programming settings to tailor system operation to specific needs. Users can adjust regeneration cycles, flow rates, and delay settings for optimized performance. Accessing these settings requires a specific key sequence to lock and unlock the program, ensuring accidental changes are prevented. The valve allows customization of regeneration timing, cycle duration, and water usage limits. Advanced settings may include adjusting fill and brine times for precise control. These features enable users to fine-tune the system for efficiency and reliability. Proper programming ensures the valve operates seamlessly with the water treatment system, meeting individual requirements effectively. Regular updates and adjustments can enhance system longevity and performance. Custom settings must be saved correctly to maintain configurations.

Safety Guidelines

- Always follow general warnings and precautions outlined in the manual.

- Handle the valve with care to avoid damage during installation or maintenance.

- Store the valve in a dry, protected area when not in use.

- Use only silicone-based lubricants to prevent component damage.

9.1 General Warnings and Precautions

Adhere to all safety guidelines to ensure proper function and longevity of the Clack WS1 control valve. Always use silicone-based lubricants exclusively, as hydrocarbons can damage components containing O-rings or plastic parts. During regeneration, ensure the brine tank contains salt and allow at least 2 hours before initiating the process. Properly support the system and plumbing, as installation fittings are not designed to bear weight. These warnings must be included in the OEM’s system manual to ensure user safety and compliance. Failure to follow these precautions may result in system malfunctions or component damage. Always refer to the manual for specific instructions and safety measures.

9.2 Proper Handling and Storage

Handle the Clack WS1 control valve with care to prevent damage. Clean the valve before storage to remove any debris or contaminants. Store in a dry, cool environment, away from direct sunlight and chemicals. Avoid exposing the valve to extreme temperatures or physical stress. During transportation, secure the valve properly to prevent movement or impact. Use original packaging if available to ensure protection. Always follow manufacturer guidelines for handling and storage to maintain the valve’s performance and longevity. Proper storage ensures the valve remains in optimal condition for installation and operation. Failure to adhere to these guidelines may void the warranty or damage the product. Ensure all components are included and undamaged before storage.

Resources and Support

Access the Clack WS1 PDF manual for detailed instructions. Explore OEM guides, troubleshooting tips, and contact Clack support for assistance. Resources are available for manufacturers and service personnel.

10.1 Accessing the Full PDF Manual

The complete PDF manual for the Clack WS1 control valve is available for download from the official Clack Corporation website or authorized distributors. This manual provides in-depth details on installation, operation, maintenance, and troubleshooting. It serves as an essential resource for both manufacturers and service personnel. To access the manual, visit the Clack WS1 series support page and follow the download link. Ensure to use the latest version for the most accurate and up-to-date information. The PDF format allows for easy printing and referencing during system setup or maintenance tasks. Regularly check for updates to stay informed about new features or technical improvements.

10.2 Clack WS1 Series Manuals and Guides

The Clack WS1 series offers a range of manuals and guides to support installation, operation, and maintenance. These resources include detailed installation instructions, operation guides, and maintenance manuals, ensuring comprehensive understanding and proper use of the control valve. The manuals are available in PDF format for easy access and printing. Designed for manufacturers, installers, and service personnel, they provide technical specifications, troubleshooting tips, and diagnostic procedures. Additional guides focus on specific features like delayed regeneration and custom programming settings. All manuals are accessible through the official Clack Corporation website or authorized distributors, ensuring users have the latest information for optimal system performance and longevity.

The Clack WS1 control valve is a robust solution for water treatment systems, offering efficient operation and customization. This manual provides essential guidance for optimal use and maintenance.

11.1 Summary of Key Points

The Clack WS1 control valve is a versatile and efficient solution for water softeners and filtration systems. It offers advanced features like delayed regeneration and customizable settings, ensuring optimal performance. Proper installation, programming, and maintenance are crucial for longevity and reliability. Regular cleaning and lubrication of components, along with timely replacement of wearable parts, are essential for smooth operation. Troubleshooting common issues and using diagnostic tools can resolve most problems effectively. This manual provides comprehensive guidance, from initial setup to advanced programming, ensuring users can harness the full potential of the Clack WS1 control valve for their water treatment needs.

11.2 Final Tips for Optimal Use

For optimal performance, ensure regular maintenance, including cleaning and lubricating components. Familiarize yourself with programming modes to customize settings for specific needs. Utilize diagnostic tools to quickly identify and resolve issues. Always follow safety guidelines during installation and operation. Refer to the manual for detailed instructions on advanced features like delayed regeneration. Proper handling and storage of the valve will extend its lifespan. By adhering to these tips, you can maximize the efficiency and reliability of the Clack WS1 control valve, ensuring it operates smoothly for years to come.